Supply Chains & Logistics

A Tale of Two Hot Sauces: Spicing Up Diversification

The dueling fortunes of two hot sauce companies demonstrate the power of strategic diversification.

The dueling fortunes of two hot sauce companies demonstrate the power of strategic diversification.

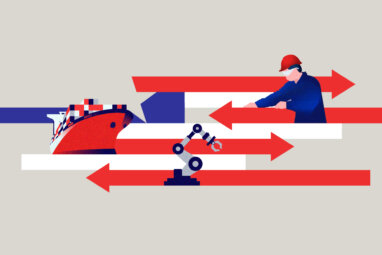

There’s a widespread belief that U.S. companies are increasingly choosing to deglobalize. But is that really happening?

A new framework can help companies fine-tune their product demand forecasting by using human and AI agents in concert.

Todd Heimes of Amazon Business shares insights on procurement and digital transformation.

To comply with new sustainability rules, consumer brands need much more visibility into products’ chemical compositions.

Geopolitics and supply chain resiliency are just two of the factors spurring some manufacturers to move back to the U.S.

This Strategy Guide offers expert insights and best practices for state-of-the-art compliance.

When organizations create forward-looking smart KPIs with AI, they see increased strategic alignment.

Research points to six practices leaders can use to overcome stakeholder resistance to automated negotiation technology.

Businesses must take a multilayered approach to effectively combat counterfeit and unauthorized sales of their products.

Supply chain risks have become nearly incalculable. Managing them requires a capabilities-driven mindset.

A more logical approach to risk management can help leaders sustain value generation through disruption and uncertainty.

Research shows that product returns decrease when online shoppers receive orders in a single, consolidated delivery.

Inflation and supply chain disruption are exposing the risks of relying on a subscription model in some markets.

Transparency about how minerals are sourced advances environmental justice and climate protection.

This issue of MIT SMR focuses on creating and managing successful, engaged teams in a pandemic-changed world.

Supply chain risks have become nearly incalculable. Managing them requires a capabilities-driven mindset.

To strengthen resiliency, companies need to build flexibility into the supply chain talent base.

Land O’Lakes’ CTO explains how data and artificial intelligence help the organization support agricultural production.

Digital twins can deliver immense benefits across a wide range of supply chains with the right implementation strategy.