Getting Past the Hype About 3-D Printing

Although additive manufacturing techniques hold great promise, near-term expectations for them are overoptimistic.

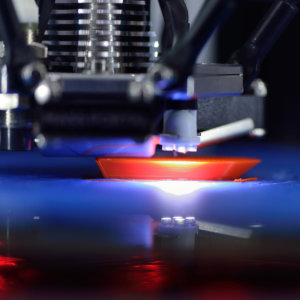

The hope for additive manufacturing is that it will revolutionize manufacturing.1 Although additive manufacturing — also known as 3-D printing — was developed back in the 1980s, it has garnered increased attention in recent years as managers look for ways to improve efficiency and reduce production costs. Managers hope that much the way GE’s new printed nozzle for jet engines has reduced the need for expensive materials and energy,2 3-D-printed parts will cut lead times and make supply chains more efficient in a wide range of settings.3

Despite the potential of additive manufacturing, we believe that near-term expectations for it are overblown. We base this conclusion on our research, which included 80 interviews as well as extensive study of the literature on the history of materials and process technologies, industry meetings, and factory visits.4 (See “About the Research.”)

Examining Three Myths

In our view, three important myths about additive manufacturing need to be dispelled. The first myth is that additive manufacturing will allow producers to make parts of any complexity as easily and economically as parts that are manufactured in traditional ways (in other words, that it will make complexity essentially “free”). The second myth is that additive manufacturing will prod manufacturing to become local. And the third myth is that additive manufacturing will allow producers to replace mass manufacturing with mass customization. None of these expectations is likely to be realized in the next several decades, especially in the case of 3-D printing in metal.

MYTH 1: Additive manufacturing allows producers to make complex parts as easily and economically as parts that are manufactured in traditional ways. Additive manufacturing makes it easier to design parts with complex geometries and internal cavities. For instance, a manufacturer using additive manufacturing would be able to make jet engine turbine blades with cooling channels. Cooling channels allow jet engines to operate at very high temperatures — so high that blades without such channels would ordinarily melt. Additive manufacturing would enable manufacturers to produce parts with more complex geometries than is currently feasible, opening the way for engines that are both cleaner and cheaper to run. It could make high-quality parts quickly.

Additive manufacturing can also allow companies to produce parts such as engine brackets that are lighter, resulting in increased fuel efficiency. In a competition organized by General Electric Co., the winning design using additive manufacturing was 80% lighter than the one it replaced.5 Additive manufacturing also enables simpler designs. In developing a new nozzle to inject fuel into the combustion chambers of its jet engines, GE, for example, merged 20 parts into one.6 Colin Chapman, the late founder of Lotus Cars, which manufactures sports and racing cars, once famously encouraged designers to “simplify, then add lightness.” Additive manufacturing makes it possible to do both.

Nevertheless, additive manufacturing has drawbacks and is subject to some restrictions. For one, parts cannot be too thin. They can’t have overhanging sections unless these are properly supported. Knowing the parameters of what’s possible requires skills that are currently scarce. Engineers (including us) have been trained on tools and approaches to design that are tailored toward conventional manufacturing. Training engineers to take advantage of the freedom that additive manufacturing will provide while understanding its limitations will require time. Indeed, limitations are still being discovered. In addition, the software tools that engineers are currently trained on may not be suited for additive manufacturing, and it is difficult to find faculty capable of teaching the new tools.7

All this is beginning to change. America Makes, a public-private consortium set up to advance additive manufacturing in the United States, currently has more than 30 academic institutions as members,8 many of which are introducing additive manufacturing into their core curricula. The new skills are being built at all levels; for example, two of the America Makes members are community colleges. Relatively inexpensive plastic 3-D printers are also appearing in high schools, thereby introducing students to their possibilities at an impressionable time.9 Some of the machines are specifically designed for educational environments.

Contrary to what many people may think, not all additive manufacturing systems and processes are the same. There are fundamental differences in terms of feedstocks, heat sources, and machine configurations. The material science behind plastic additive manufacturing is totally different than the material science of metal additive manufacturing — and expertise in one doesn’t easily transfer to another. Each requires a long learning process adapted to the particular application.

In the labor market, there is growing demand for people who have been educated in additive manufacturing processes. In addition to those with bachelor’s degrees, there are opportunities for master’s degree holders who have the skills to set up, operate, and troubleshoot 3-D printing machines.

In addition to training issues, there are safety issues and technical issues. Some of the safety concerns stem from the fact that the technology is new. In an effort to reduce the possibility that parts will fail, some manufacturers are using parts that are heavier than optimal. Clever new structures such as very light meshes have different vulnerabilities than solid, chunky components; this is especially true in applications where parts need to rotate or are repeatedly loaded and unloaded. Understanding these potential weaknesses, and learning to design parts to avoid them, will take time.

On top of that, more work needs to be done to reduce variability, so that additive manufacturing machines and processes can produce components that are identical given the same set of inputs.10 To understand why this is important, it’s helpful to recognize a fundamental difference between 3-D printing and other manufacturing technologies. Take machining, for example. Machining involves starting with a block of metal and cutting away the parts you don’t need. It’s reasonable to expect that after the machining process the material that’s left has essentially the same properties as the block you started with. But that is not necessarily the case when a part is made with 3-D printing.

That’s because some metallic additive manufacturing involves zapping adjacent microscopic particles of a powder with a powerful laser so that the particles melt and fuse. The process of zapping particles occurs over and over — millions, perhaps billions, of times — until the part is completed. Each particle in the resulting component is rapidly heated and cooled many hundreds of times. What finally emerges depends on a number of factors, including how much each particle was heated, how many particles were heated at one time, how many times the particles were heated, and how quickly they cooled. If the process is not consistent from beginning to end, you can’t have consistent results.

To ensure that the process has been properly controlled requires finished-part testing. However, some of the necessary testing methods — for example, how to inspect the insides of hollow parts without having to slice them open and destroy them — are still being invented. Ultrasound does not always work well for metals, and another technology, industrial CT scanning, is slow and expensive, and cannot be used for all geometries.11 Yet unless we can resolve these issues, the savings that might be generated by one-step manufacturing processes, especially for parts critical to product safety, could be swallowed up by the need for additional testing.

Quality control is challenging enough when components are made within the same four walls; working with third-party suppliers makes for even greater difficulty. A part made using additive manufacturing that performs well on tests designed for conventionally produced components may for a variety of reasons perform poorly in service. For example, although the properties at the surface of a part may be the same, they could be different from those a few millimeters deep.

Initiatives are underway to solve these problems. ASTM International and the International Organization for Standardization are collaborating to develop standards for additive manufacturing.12 In the United States, the Materials Genome Initiative, an interagency program designed to create public policy and infrastructure for the development of advanced materials, aims to create powerful software simulation tools and create shared material databases.13

Some companies are pushing the boundaries of additive manufacturing with new materials and techniques. For example, Impossible Objects LLC of Northbrook, Illinois, is applying additive manufacturing techniques to composite materials, to produce components that are much stronger than ordinary plastics; these materials can use high-throughput manufacturing techniques that have traditionally been applicable only to plastics. Another startup, XJet Ltd., of Rehovot, Israel, is suspending metallic particles in ink so that metallic parts can be printed using fast printing technologies.

While there are a number of innovative startups like Impossible Objects and XJet, the road to the mass market for products and technologies that cater to safety-critical applications can be long. GE recently announced that it would acquire a majority ownership stake in Concept Laser GmbH, a supplier of additive manufacturing equipment that is based in Lichtenfels, Germany, and that was founded in 2000. In 2012, GE Aviation purchased Morris Technologies Inc., an additive manufacturing company that was founded in 1994. Indeed, it has taken an amalgamation of GE’s own investments and decades of investments by others to bring additive manufacturing to market in the aerospace industry. Smaller companies that seek to master more basic additive manufacturing materials and processes may want to begin by building products where requirements for safety and reliability are less stringent than they are in aerospace.

MYTH 2: Additive manufacturing will encourage manufacturing to become local. Many people are anticipating that additive manufacturing will bring manufacturing closer to markets and consumers.14 But in our opinion, this scenario has been greatly exaggerated. In concept, the idea of sending raw materials, instead of finished products, to a manufacturing location close to the users so the company can produce on demand what’s needed makes sense. A company could have machines and raw materials in cities and neighborhoods where its customers are, produce in the right quantities, and thereby reduce lead times while cutting transportation and inventory costs.

However, additive manufacturing, like other methods of production, is subject to economies of scale. Since it takes skilled operators and sophisticated machines to produce reliable and durable products using 3-D printing, having one person in charge of 10 machines would be cheaper than producing at 10 different locations with one person each. Furthermore, additive manufacturing parts often require a number of complex postproduction steps and tests, many of which require specialized machinery of their own. For a simple titanium-alloy aerospace component, such costs would make up 10% to 15% of the total cost of the component.15 Clearly, it’s better to do the postproduction work at one site to support many different machines than to distribute the capability across multiple locations.

Companies should, however, use additive manufacturing to accelerate and streamline product development. For example, additive manufacturing allows designers to produce and test prototypes for a wide range of concepts, which may not require extensive post-processing or rigid quality control. Early feedback on prototypes avoids expensive surprises later in the product development process. Additive manufacturing also makes it possible to build tools for short production runs. This enables companies to beta test physical products. For example, the automotive molds industry in Portugal uses simple prototype molds to produce sample components.16 Because successful product development requires early and frequent engagement with customers, there are clear advantages to being able to do this locally.

Nevertheless, we think many governments would be making a mistake to invest large sums of public money in developing a broad additive manufacturing capability in the hope of “bringing back manufacturing.” The United States, China, Singapore, and the European Union are investing hundreds of millions of dollars in national programs to create new or retain existing competitive advantages in manufacturing.17 The United States, for its part, has identified additive manufacturing as critical to maintaining its technological superiority in the military and in aerospace. However, the case for public investment in building additive manufacturing capability is less compelling for other countries, particularly when the local market isn’t large enough for the economies of scale that a capital-intensive technology needs. For example, our conversations with Portuguese manufacturers revealed that additive manufacturing parts made in Germany had better mechanical properties due to manufacturers’ greater know-how and were also cheaper than similar parts manufactured in Portugal by suppliers who catered only to the Portuguese market.

In our view, governments should concentrate on identifying sectors in which their industries are already competitive and support the development of focused additive manufacturing capabilities in those sectors. Portugal’s highly successful automotive mold makers, for example, may need to incorporate additive manufacturing into their suite of capabilities in order to meet customer expectations of fast lead times and performance. But the possibilities for another country such may be different.

MYTH 3: Additive manufacturing will allow producers to replace mass manufacturing with mass customization. Many people have predicted that additive manufacturing will result in a decisive shift from mass manufacturing to mass customization.18 But the likelihood that this will occur quickly is slim. Wohlers Associates Inc., a leading additive manufacturing consulting firm, estimates that in the long term additive manufacturing might represent 5% of total manufacturing worldwide.19 Moreover, there are forces other than additive manufacturing that will hasten mass customization. The Spain-based fashion retailer Zara, for example, is able to launch a new collection within weeks. Rather than using additive manufacturing within local markets, it achieves this by managing its supply chain masterfully.20 Manufacturers of IT hardware, for their part, have relied on modularization to assemble bespoke products on demand, and to do so close to their customers.21

We see limits on the extent to which additive manufacturing will be flexible manufacturing. In theory, a good 3-D printer ought to be capable of printing a wide range of designs. In practice — and especially in applications critical to safety — we may see regulations that control how 3-D printers and additive manufacturing equipment in general can be configured. This could mean that every time a machine is reset to produce a part that’s different from the one it made before, the system will have to be rechecked. Depending on what this entails and how involved the inspection is, it might turn out to be less costly and safer to have different machines dedicated to the production of different parts.

To be sure, additive manufacturing’s flexibility can be, and is being, harnessed to produce products where safety standards are less of an issue — for example, wearable technologies and jewelry. Companies will find the use of additive manufacturing for such products increasingly appealing as production speeds improve and costs decline. (See “Should You Move Into Additive Manufacturing?”) For example, last May, HP Inc. delivered its first polymer additive manufacturing machine, which it claimed was up to 10 times faster than previous models and cost half as much.22

In general, additive manufacturing holds great promise, but in many areas the cart has gotten ahead of the horse. Much of the technology is still under development. The history of comparable technologies such as composite materials and high-performance castings shows that the problems may take decades to resolve. For now, additive manufacturing is cost-competitive only in niche applications — for instance, those involving plastics. Businesses that want to plunge into additive manufacturing should be cognizant of the challenges. Determining whether it makes sense to invest in additive manufacturing will require experimentation and learning.

References (22)

1. R.A. D’Aveni, “3-D Printing Will Change the World,” Harvard Business Review 91, no. 3 (March 2013): 34.

2. T. Kellner, “World’s First Plant to Print Jet Engine Nozzles in Mass Production,” GE Reports, July 15, 2014, www.gereports.com; and M. LaMonica, “GE, the World’s Largest Manufacturer, Is on the Verge of Using 3-D Printing to Make Jet Parts,” n.d., www.technologyreview.com.

Comments (2)

DR ROGER E BOHN

Syed Aashir Hussain