The Problem With Digital Design

Yes, digital design is a wonderful tool. But unless it is supported with strong management processes, there can be unintended — and negative — consequences.

Today’s product development is nearly all digital — allowing teams to go from idea to precise parts quickly, and permitting them to continually revise and validate throughout the development process.

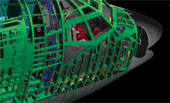

Image courtesy of Boeing.

The widespread adoption of digital design shows that it makes a powerful contribution to R&D effectiveness and efficiency. Design tools can be invaluable in visualizing ideas, quickly developing a detailed design and conducting fast iterations. On the surface, these are all good things. Yet our research suggests that digital design is not a panacea. Unless it is complemented with sound management practices, unforeseen problems will be introduced into the product development process.

Some background will help explain why. It is well known that since the 1980s, the new product development process has evolved from traditional engineering teams working together in one place to an approach that is more global and virtual.1 One major factor that has enabled this transition has been the proliferation of digital design tools such as highly capable computer aided design packages (such as Parametric Technology Corp.’s PTC Creo Elements/Pro (formerly Pro/ENGINEER), Dassault Systèmes’ CATIA and SolidWorks), rapid prototyping technologies (such as 3D printers), and collaboration tools (such as Microsoft SharePoint, Google Docs and project wikis).

The Leading Question

What potential downsides does digital design introduce into product development?

Findings

- Digital design tools can make the work appear complete before it actually is, creating problems down the line.

- Because the tools are simple to use, they can promote endless tinkering, delaying production.

- Strong managers — and well-defined management processes — are needed to guard against both potential problems.

A second factor leading to increased use? Lower prices. Today, capable CAD packages can cost as little as a few hundred dollars and can run efficiently on desktop or laptop computers costing a fraction of those required just five years ago.

One of the most widely studied payoffs of digital design was the Boeing 777, which was designed, modeled and tested virtually by an extended development team.2 The benefits of this approach included identifying part interference and fit issues before expensive physical prototyping and having different members of the organization (customers, manufacturing representatives, vendors, service and maintenance individuals, etc.) view and participate simultaneously in the design process.

References (13)

1. S.D. Eppinger and A.R. Chitkara, “The New Practice of Global Product Development,” MIT Sloan Management Review 47, no. 4 (summer 2006): 22-30.

2. K. Sabbagh, “Twenty-First Century Jet: The Making and Marketing of the Boeing 777” (New York: Scribner, 1996).