Cracking the Code of Mass Customization

Most companies can benefit from mass customization, yet few do. The key is to think of it as a process for aligning a business with its customers’ needs.

Topics

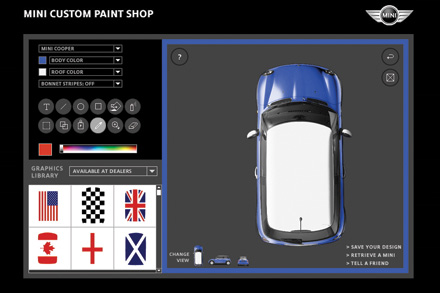

Mini Cooper customers can design the roofs of their vehicles by using an online tool kit. That software has enabled BMW to tap into the custom after-sales market.

Courtesy of Mini Cooper.

The concept of mass customization makes sense. Why wouldn’t people want to be treated as individual customers, with products tailored to their specific needs? But mass customization has been trickier to implement than first anticipated, and many companies soured on the approach after a number of high-profile flops, including Levi Strauss & Co.’s failed attempt at manufacturing custom jeans. Now, executives tend to think of mass customization as a fascinating but impractical idea, the preserve of a small number of extreme cases, such as Dell Inc. in the PC market.

Our research suggests otherwise. Over the past decade, we have studied mass customization at a number of different organizations, including a survey of more than 200 manufacturing plants in eight countries. (See “About the Research.”) From that investigation, we found that mass customization is not some exotic approach with limited application. Instead, it is a strategic mechanism that is applicable to most businesses, provided that it is appropriately understood and deployed. The key is to view it basically as a process for aligning an organization with its customers’ needs. That is, mass customization is not about achieving some idealized state in which a company knows exactly what each customer wants and can manufacture specific, individualized goods to satisfy those demands—all at mass-production costs. Rather, it is about moving toward these goals by developing a set of organizational capabilities1 that will, over time, supplement and enrich an existing business.

That set of fundamental capabilities is threefold: (1) the ability to identify the product attributes along which customer needs diverge, (2) the ability to reuse or recombine existing organizational and value-chain resources and (3) the ability to help customers identify or build solutions to their own needs. Admittedly, the development of these capabilities requires changes that are often difficult because of powerful inertial forces in an organization, but that makes the argument more compelling: Those companies that are able to develop the capabilities will be able to enjoy long-lasting competitive advantages. In addition, we believe that many obstacles can be overcome by using a variety of approaches, and that even small improvements can reap substantial benefits.

References

1. For a definition of the concept of strategic capabilities, see K.M. Eisenhardt and J.A. Martin, “Dynamic Capabilities: What Are They?” Strategic Management Journal 12, no. 10 (2000): 1105-1121.

2. J.B. Pine II, “Mass Customization—The New Frontier in Business Competition” (Cambridge, Massachusetts: Harvard Business School Press, 1993).

3. Paul Zipkin discussed some of the capabilities of mass customization in an earlier article, P. Zipkin, “The Limits of Mass Customization,” MIT Sloan Management Review 42, no. 3 (2001): 81-87. The derivation of the three fundamental capabilities builds on work by F. Salvador, M. Rungtusanatham, A. Akpinar and C. Forza, “Strategic Capabilities for Mass Customization: Theoretical Synthesis and Empirical Evidence,” Academy of Management Proceedings (2008): 1-6.

4. Spotting unaddressed differences among customers is not an easy task because information about customers’ unfulfilled needs is “sticky”—that is, difficult to access and codify for the solutions provider. While this problem is shared by both mass producers and mass customizers, it is more demanding for the latter because of the extreme fragmentation of customers’ preferences. The notion that the information regarding customer needs is sticky has been discussed extensively by Eric von Hippel. See E. von Hippel, “Economics of Product Development by Users: The Impact of ‘Sticky’ Local Information,” Management Science 44, no. 5 (1998): 629-644. Ogawa and Piller discuss the resulting problems in S. Ogawa and F.T. Piller, “Reducing the Risks of New Product Development,” MIT Sloan Management Review 47, no. 2 (2006): 65-71.

5. Virtual concept testing has been described in E. Dahan and J.R. Hauser, “The Virtual Customer,” Journal of Product Innovation Management 19, no. 5 (2002): 332-353.

6. J.B. Pine II, J.H. Gilmore and A.C. Boynton, “Making Mass Customization Work,” Harvard Business Review 71, no. 5 (1993): 108-118.

7. Ibid.

8. The “burden of choice” problem in mass-customization systems was described first in C. Huffman and B.E. Kahn, “Variety for Sale: Mass Customization or Mass Confusion?” Journal of Retailing 74, no. 4 (1998): 491-513. Franke and Piller looked at this challenge in an empirical study described in N. Franke and F. Piller, “Value Creation by Toolkits for User Innovation and Design: The Case of the Watch Market,” Journal of Product Innovation Management 21, no. 6 (2004): 401-415.

9. R. Desmueles, “The Impact of Variety on Consumer Happiness: Marketing and the Tyranny of Freedom,” Academy of Marketing Science Review 12 (2002).

10. Consider another example of matching: Zafu has created a very profitable business at zafu.com by taking body measurements of customers and then recommending the best-fitting pair of jeans out of the existing assortments of many major brands. From their users’ perspective, Zafu is offering a product that fits like tailor-made jeans. But from the fulfillment perspective, Zafu is just matching standard inventory with individual needs.

11. The APC case is documented in L. Hvam, “Mass Customization in the Electronics Industry,” International Journal of Mass Customization 1, no. 4 (2006): 410-426.

12. M. Rungtusanatham and F. Salvador, “Transitioning from Mass Production towards Mass Customization: Hindrance Factors, Structural Inertia and Transition Hazard,” Production and Operations Management 17, no. 3 (2008): 385-396.

13. J. Lampel and H. Mintzberg, “Customizing Customization,” Sloan Management Review 38, no. 1 (1996): 21-30.

i. F. Salvador, M. Rungtusanatham, A. Akpinar and C. Forza, “Strategic Capabilities for Mass Customization,” Journal of Operations Management, in press. (Note: A shortened version of the article is included in the 2008 Academy of Management Best Paper Proceedings.)

ii. N. Franke and F. Piller, “Value Creation by Toolkits for User Innovation and Design: The Case of the Watch Market,” Journal of Product Innovation Management 21, no. 6 (2004): 401-415.

iii. M. Rungtusanatham and F. Salvador, “Transitioning from Mass Production to Mass Customization—Hindrance Factors, Structural Inertia and Transition Hazard,” Production and Operations Management, in press.

iv. S. Ogawa and F.T. Piller, “Reducing the Risks of New Product Development,” MIT Sloan Management Review 47, no. 2 (2006): 65-71; P. Martin de Holan, N. Phillips and T. Lawrence, “Managing Organizational Forgetting,” MIT Sloan Management Review 46, no. 4 (2004): 45-51; and F. Salvador, C. Forza and M. Rungtusanatham, “Modularity, Product Variety, Production Volume and Component Sourcing: Theorizing Beyond Generic Prescriptions,” Journal of Operations Management 20, no. 5 (2002): 549-575.

v. F. Salvador, “Towards a Product Modularity Construct: Literature Review and Reconceptualization,” IEEE Transactions on Engineering Management 54, no. 2 (2007): 219-240; F.T. Piller, “Mass Customization: Reflections on the State of the Concept,” International Journal of Flexible Manufacturing Systems 16, no. 4 (2005): 313-334; and F. Piller, K. Moeslein and C. Stotko, “Does Mass Customization Pay?” Production Planning & Control 15, no. 4 (2004): 435-444.

vi. C. Forza and F. Salvador, “Information Management for Mass Customization: Connecting Customer, Front-end and Back-end for Fast and Efficient Personalization” (London: Palgrave Macmillan, 2007); and M.M. Tseng ansd F.T. Piller, “The Customer Centric Enterprise: Advances in Mass Customization and Personalization” (New York: Springer, 2003).

Comments (2)

Ajit Kini

bruces